Maximum value added

The measurement data from the high-resolution true shape measurement system JORO-3D or JORO-3D ++ forms the basis for optimisation with JORO-optima3D. Due to the large amount of detailed master information, the maximum value added is possible in this multi-stage optimisation. There are generally several ways to deploy cutting optimisation and implement it in your company.

In the sawmill:

Taking into account all system parameters, the software is adapted to your products and orders. Here, quality specifications, wane rules and production-related specifications for each main and side product are included in the calculation.

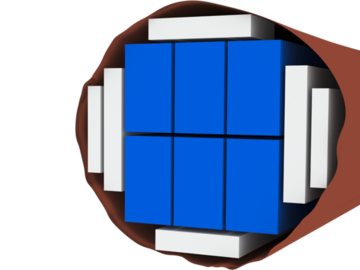

- Main products – The optimum result from all possible combinations is determined.

- Side products – All possible side product combinations are calculated and the best result is determined.

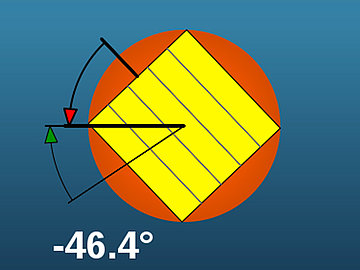

- Insertion angle – The exact angle for the insertion is determined.

In a further configuration stage, the cutting machine will be given all the data for the control of the saw line directly at the incision.

At the log yard with recognition in the sawmill:

In this configuration stage, slice optimisation is already carried out at the log yard on short and long timber. With this shift, the added value and yield increase again, since there are even more opportunities for optimisation. The data for each section is stored and available in a database. Once a pile is cut in, this data is used for further recognition. In the measurement in front of the saw line, the respective section is recognised and the existing optimisation data is assigned.

Jacob Fehr

Phone: +49 8386 9360-25<br/> Mobile: +49 171 5712182<br/> E-mail: j.fehr@je-gmbh.de

Products

JORO-optima3D is best combined with the following products:

- JORO-3D

- JORO 3D ++

- JORO-3D-SCANplus

- JORO-X